EnveoTherm Premium EPS

EnveoTherm Premium is a certified facade system designed for residential and commercial buildings, suitable for both new construction and renovation of older structures. This facade system is composed of carefully selected Enveo products, combined to achieve a high-quality facade assembly, engineered for long-term functionality.

The insulation element of the system can consist of white EPS, graphite EPS Triglav, or Clima thermal insulation boards. The final decorative layer offers a choice of specially formulated facade renders, tailored to meet the specific performance requirements and location of the building.

Benefits of EnveoTherm Premium EPS Facade System

Protects structural elements and extends the building’s lifespan

Saves energy during heating and cooling

Prevents thermal bridges and improves the facade’s aesthetic quality

Increases the building’s value

Creates a more comfortable interior environment

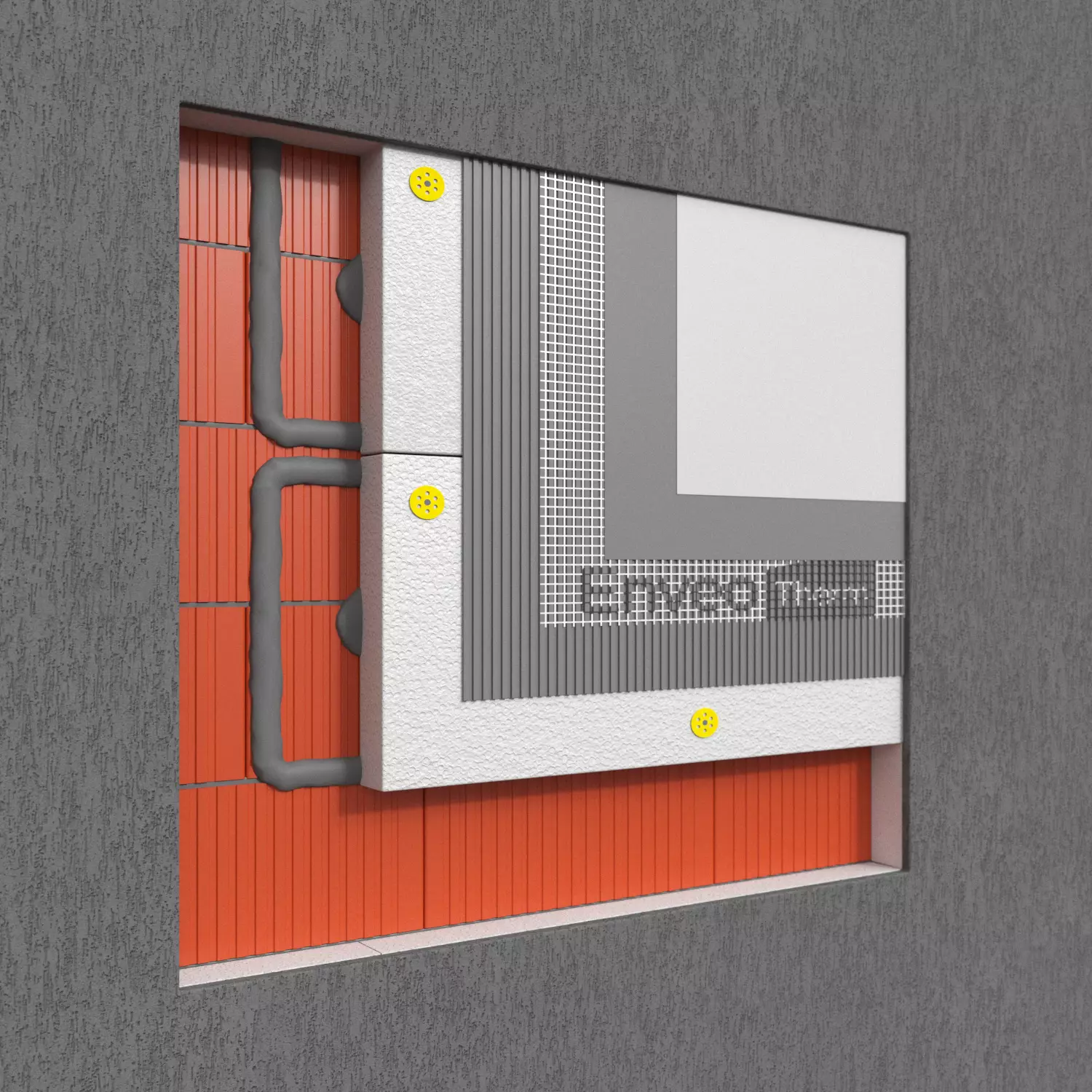

Composition of the ENVEO Facade System

1 Enveo Kleber Excellent/Premium/Premium Light - Adhesive for Bonding

2 EPS White/Grey/Triglav/Clima - Insulation Board

3 ETAG 014 - Dowels

4 Enveo Kleber Excellent/Premium/Premium Light - Adhesive for Reinforcement

5 EnveoTherm Mesh 117 50 / 131 50 / 3F 50 - Facade Mesh

6 EnveoTherm Mesh 117 50 / 131 50 / 3F 50 - Facade Mesh

7 EnveoPutz Premium Silicon/Aqua/Clean/Active – Wet Renders

| COMPONENT | PRODUCT | CONSUMPTION |

|---|---|---|

Adhesive for Bonding | EnveoKleberExcellent | ≥ 5,0 kg/m² |

Insulation Board | EPS White | 1,0 m²/m² |

Dowels | All with ETAG 014 | ≥5 kom/m² |

Reinforcement Adhesive | EnveoKleberExcellent | ≥ 5,0 kg/m² |

Facade Reinforcement Mesh | EnveoTherm Mesh 117 50 | 1,1 m’/m² |

Facade Primer | EnveoGrund | 0,25 kg/m² |

Wet Renders | EnveoPutz Premium Silicon | 2,0-3,5 kg/m² |

Installation Instructions

Thermo-insulation boards EPS White/Grey/Triglav should be glued to the previously prepared substrate using EnveoKleber Excellent/Premium/Premium Light adhesive, applying the edge-point method. When bonding the boards, place them tightly next to each other, ensuring that the joints of the boards do not align with the edges of openings. Detailed instructions for substrate preparation, product preparation, and installation can be found in the product technical data sheets via the QR Code or at www.saint-gobain.rs.

Anchoring can begin no earlier than 48 hours after bonding. Fasteners should be anchored through the adhesive at the joints and through the center of the insulation board. The minimum number of anchors per square meter must be at least 5 pieces, and the exact number must be calculated by an engineer, considering the height of the building, wind zone, etc. More detailed product instructions can be found via the QR code or at www.saint-gobain.rs.

Before reinforcing the entire surface, install the necessary profiles with mesh (corner, drip, contact, etc.) as well as reinforcements at the corners around openings. Reinforcement using EnveoKleber Excellent/Premium/Premium Light adhesive should be performed with EnveoTherm Mesh 117 50/131 50/3F 50 with overlaps of 10 cm, ensuring that the total thickness of the adhesive after covering the mesh is at least 5 mm. During installation, position the mesh in the outer third of the adhesive, thus providing high resistance of the system against external influences. Detailed instructions about the products and their application can be found via the QR code or at www.saint-gobain.rs.

Apply Enveo Grund primer in one to two layers on the well-dried EnveoKleber Excellent. It is essential that the surface is completely covered with a white or tinted primer according to the shade of the facade mortar from the EnveoTherm Mix system. Detailed product instructions can be found via the QR code or at www.saint-gobain.rs.

Before use, thoroughly mix EnveoPutz facade decorative plaster and prepare the material for the designated surface.. After that, proceed to install the products in a synchronized manner, keeping the joints of the materials according to the principle of wet-on-wet to ensure that they are not visible after completion. The air and substrate temperature during installation and drying must not be lower than 5°C or higher than 30°C. Protect the material from adverse weather conditions for at least 24 hours. Detailed instructions about the products can be found via the QR code or at www.saint-gobain.rs.