EnveoTherm Excellent EPS

EnveoTherm Excellent is a certified facade system designed for residential and commercial buildings, suitable for both new constructions and renovations of older structures. The system's durability and thermal insulation are ensured through selected Enveo products, which, when combined, create a high-quality facade assembly designed to make the facade durable.

The insulating element of the system can consist of either white or graphite styrofoam, while the final decorative layer offers a choice between silicate and silicone facade plasters.

Benefits of EnveoTherm Excellent EPS Facade System

Protects structural elements and extends the building’s lifespan

Saves energy during heating and cooling

Prevents thermal bridges and improves the facade’s aesthetic quality

Increases the building’s value

Enhances the building’s sound insulation

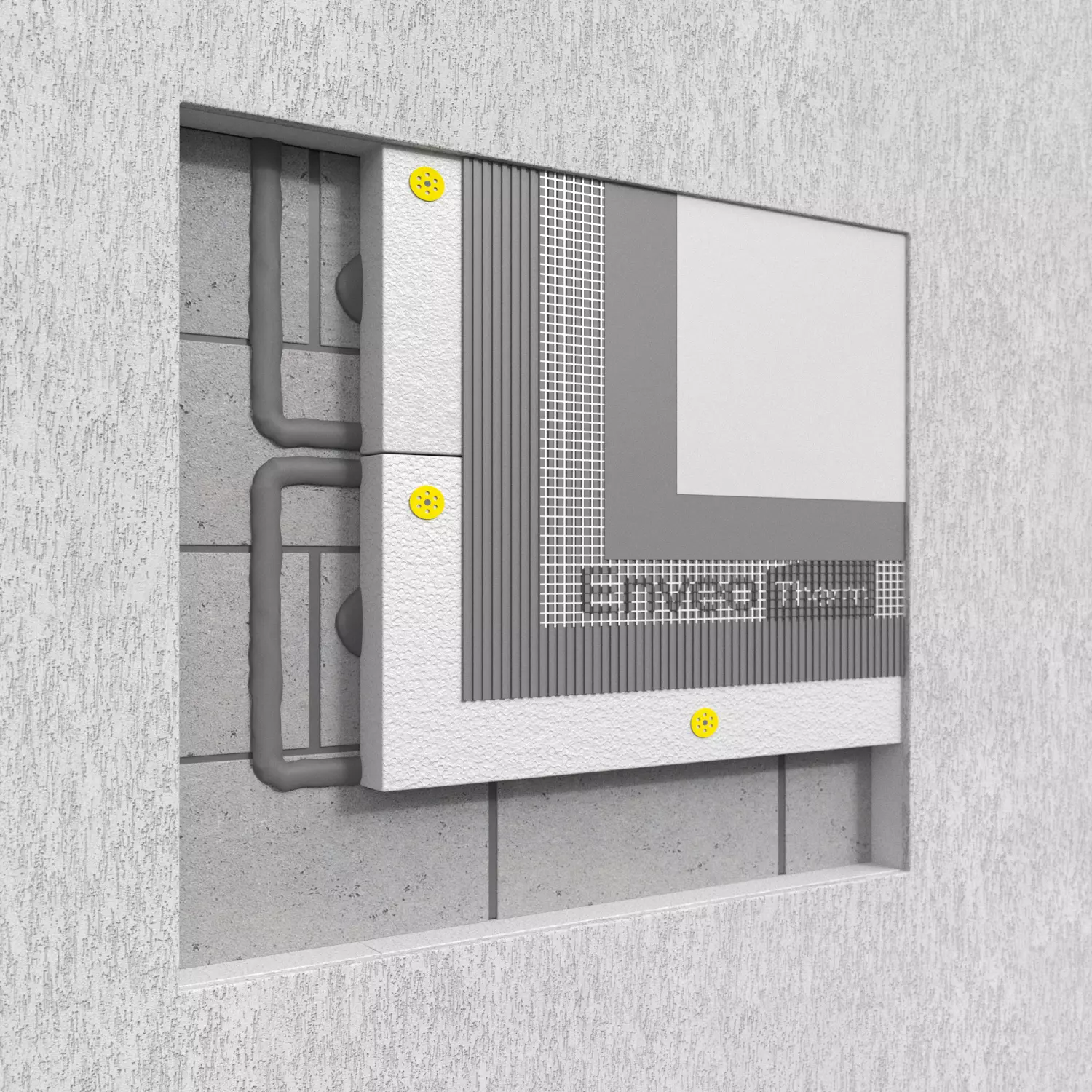

Composition of the ENVEO Facade System

1 EnveoKleber Excellent – Adhesive for Bonding Thermal Insulation (TI) Boards

2 Type: EPS White / Graphite

3 ETAG 014 – Anchor/Dowel

4 EnveoKleber Excellent – Adhesive for Reinforcing Mesh

5 EnveoTherm Mesh 117 50 – Facade Mesh

6 Enveo Grund – Facade Primer

7 EnveoPutz Silicate/Silicone – Wet Renders

| COMPONENT | PRODUCT | CONSUMPTION |

|---|---|---|

Adhesive for Bonding | ≥ 5.0 kg/m² | |

Insulation Board | EPS White / EPS Grey | 1,0 m²/m² |

Dowels | All with ETAG 014 | ≥5 kom/m² |

Reinforcement Adhesive | ≥ 5,0 kg/m² | |

Facade Reinforcement Mesh | 1,1 m’/m² | |

Facade Primer | 0,25 kg/m² | |

Wet Renders | 2,0-3,5 kg/m² |

Installation Instructions

Thermal insulation boards Isover Boards TR 5 - TR 15 and Isover Lamella should be bonded to a previously prepared substrate using EnveoKleber Excellent adhesive. For rock wool boards, it is necessary to impregnate the boards with adhesive, and then apply the adhesive using the perimeter-dot method. For bonding lamella boards, it is essential to apply adhesive across the entire surface of the lamella. When bonding the boards, place them tightly next to each other and ensure that the joints of the boards do not align with the edges of openings. Detailed instructions for substrate preparation, adhesive preparation, and product installation can be found in the product's technical data sheet via the QR code or at www.saint-gobain.rs.

Directly or 24 hours prior to reinforcing the complete surface, install the necessary profiles with mesh (corner, drip, contact, etc.) and reinforcements at the corners around openings.

The reinforcement using EnveoKleber Excellent adhesive should be done with EnveoTherm Mesh 117 50 facade mesh, ensuring an overlap of 10 cm. The total thickness of the layer after covering the mesh with adhesive should be at least 5 mm. During installation, position the mesh within the outer third of the adhesive layer to ensure high resistance of the system to external influences. Detailed instructions about the products can be found via the QR code or at www.saint-gobain.rs.

Directly or 24 hours prior to reinforcing the complete surface, install the necessary profiles with mesh (corner, drip, contact, etc.) and reinforcements at the corners around openings.

The reinforcement using EnveoKleber Excellent adhesive should be done with EnveoTherm Mesh 117 50 facade mesh, ensuring an overlap of 10 cm. The total thickness of the layer after covering the mesh with adhesive should be at least 5 mm. During installation, position the mesh within the outer third of the adhesive layer to ensure high resistance of the system to external influences. Detailed instructions about the products can be found via the QR code or at www.saint-gobain.rs.

Apply Enveo Grund primer to the well-dried EnveoKleber Excellent in one or two layers. It is essential that the surface is completely covered with white or tinted primer according to the shade of the facade plaster from the EnveoTherm Mix system. Detailed instructions about the product and its application can be found via the QR code or at www.saint-gobain.rs.

Before use, thoroughly mix EnveoPutz wet renders and prepare the material for the designated surface. After that, proceed with the installation of the product in a synchronized manner, keeping the material joints in a "wet-on-wet" principle to ensure they are not visible after completion. The air and substrate temperature during installation and drying must not be lower than 5°C or higher than 30°C. Protect the material from adverse atmospheric conditions for at least 24 hours. Detailed instructions about the products can be found via the QR code or on the website www.saint-gobain.rs.

Video